Hymmen Machinery

Technologies For Excellent Surfaces

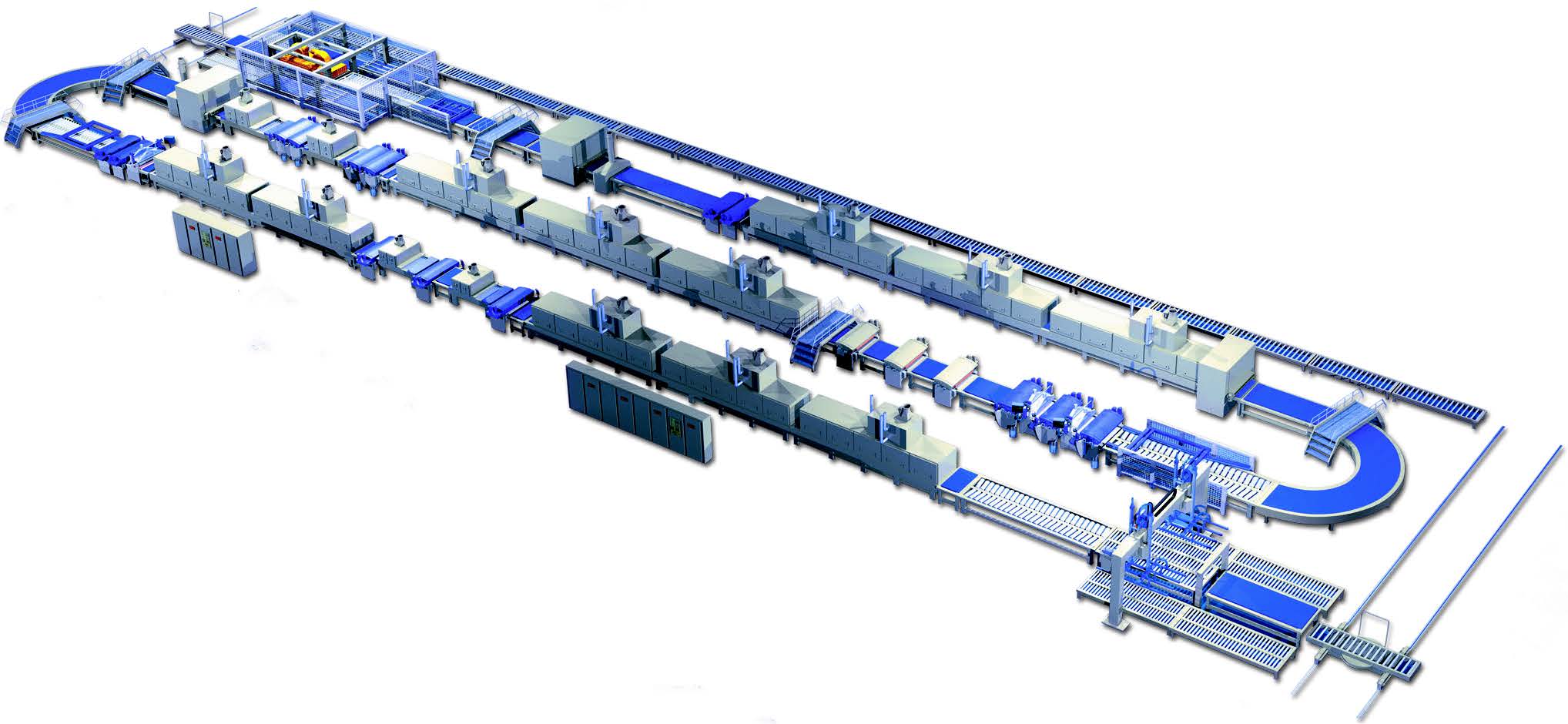

Digital Printing Lines

Since 2007, Hymmen GmbH has been the leader in producing digital printing lines for direct board and decor paper to meet the demand for design and style choices in today’s decorative surfaces. Hymmen GmbH digital printing systems offer flexibility and speed without compromising quality. These industrial, single-pass machines offer board producers repeatable and reliable performance synonymous with the Hymmen GmbH name.

Hymmen GmbH is at the forefront of digital lacquering embossing technology for the flooring and furniture industries. This DLE Plus technology offers deeper embossing with sharper edges, creating a “better-than-nature” finish for a high-production manufacturing environment. This is literally the best wood ever printed!

EMS provides full support for Hymmen GmbH digital printing and lacquering embossing systems, including spare parts and technical services.

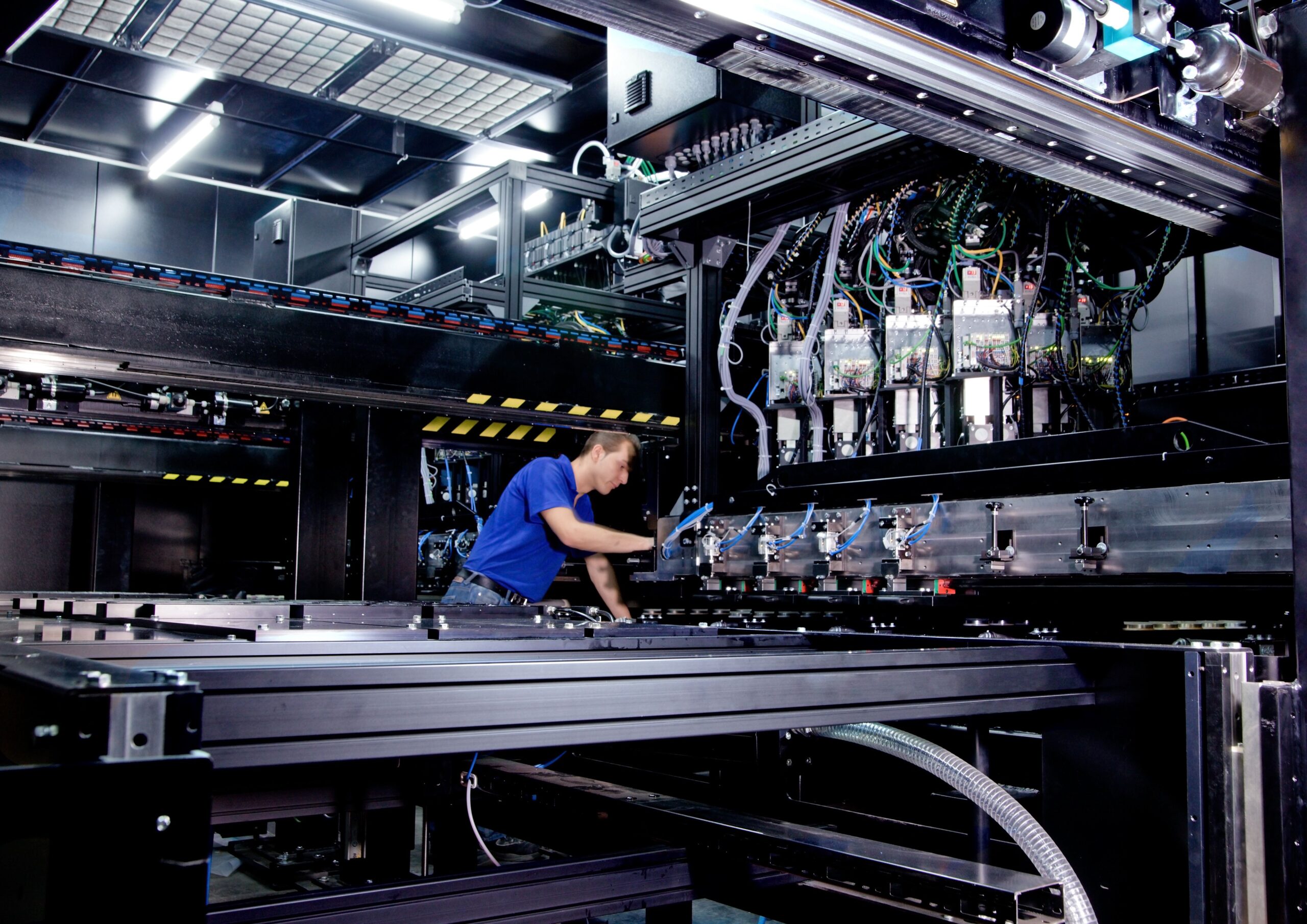

Double-Belt Presses

Hymmen GmbH offers a wide range of double-belt presses for high- and continuous-pressure laminate production. These double-belt press systems provide manufacturers reliable, continuous, and flexible production for a variety of applications and materials. Our portfolio includes isobaric and isochoric press systems.

Gain significant savings in personnel, material, and energy costs with a Hymmen GmbH double-belt press!

Multi-Daylight Press

For large-batch operations, Hymmen GmbH offers multi-day or multi-opening press systems. These advanced machines are ideal for processing large batches of products in short cycle times. The design of the Hymmen GmbH multi-daylight press utilizes precision-built pressing frames that ensure even pressure distribution over the entire pressing surface. The heating plates are built for optimal heat flow, and the upper sheet clamping guarantees safe positioning of the material, eliminating product damage. Because the board-guiding system and heating plates are combined in one efficient system, cost savings are immediate.

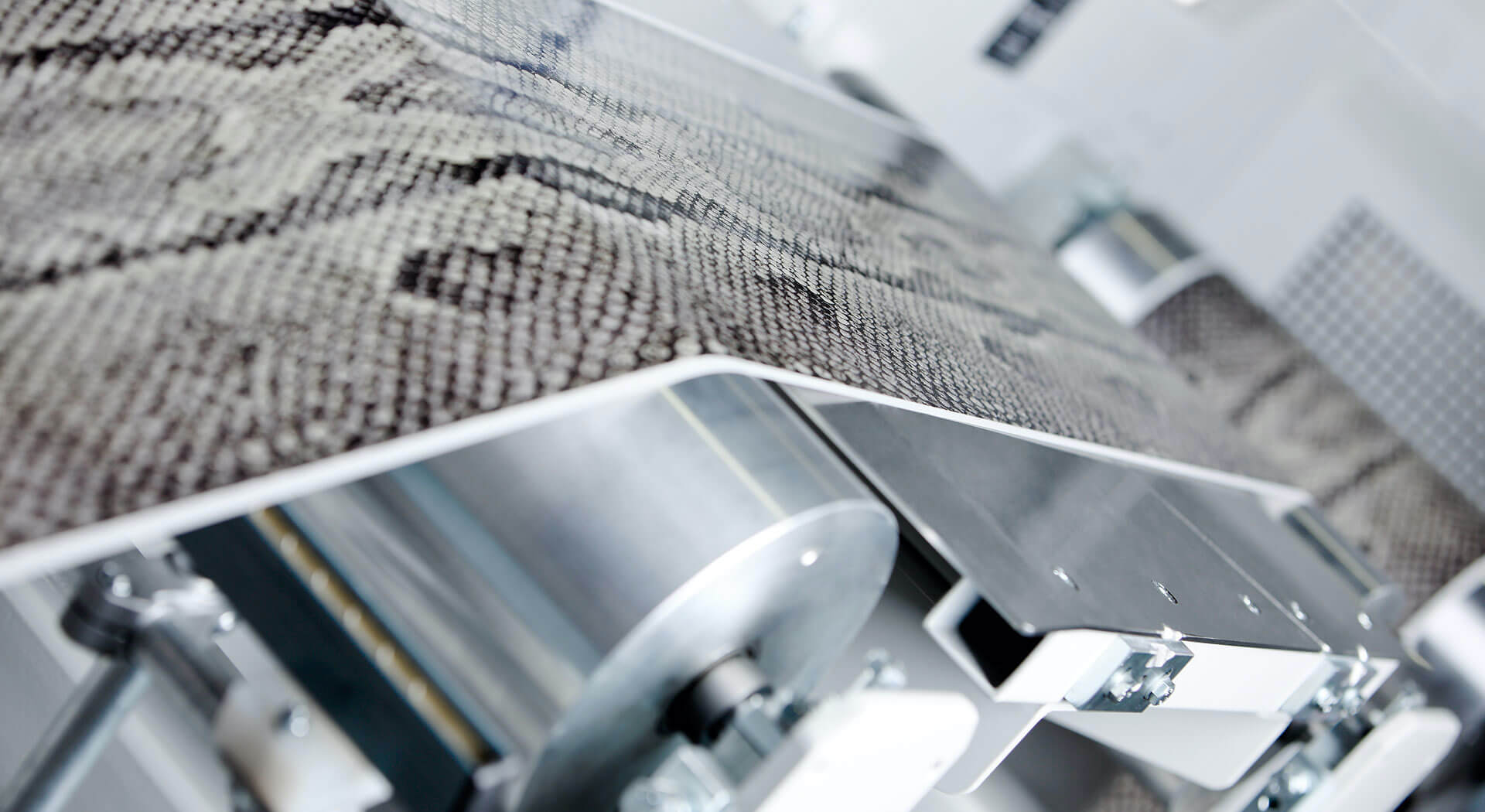

Hymmen GmbH Liquid Coating Lines

The Hymmen GmbH portfolio of liquid coating lines covers all areas of application: from simple manual operation through to higher-level electronic control systems.

Our lines enable the processing of a huge spectrum of application media, such as stains, oils, UV and water-based coatings, and filler and printing inks, in application widths of 400 mm to 2,800 mm. Special filler and smoothing machines, combined with the right curing technologies, ensure efficient coating and outstanding surface qualities.

Your advantage: individual application-oriented solutions for all areas of application – from skilled trades through to industrial production.

EMS-Service for the Hymmen GmbH Technologies

As a trusted partner, EMS provides the full range of service and spare parts for all Hymmen GmbH machinery, ensuring your operations run smoothly. We also offer expert optimization of your value-added chain with state-of-the-art upgrades for Hymmen GmbH plants and machinery.