Brandenburger – Thermal Insulation | Insulation Components | Safety | Efficiency | Cost Savings

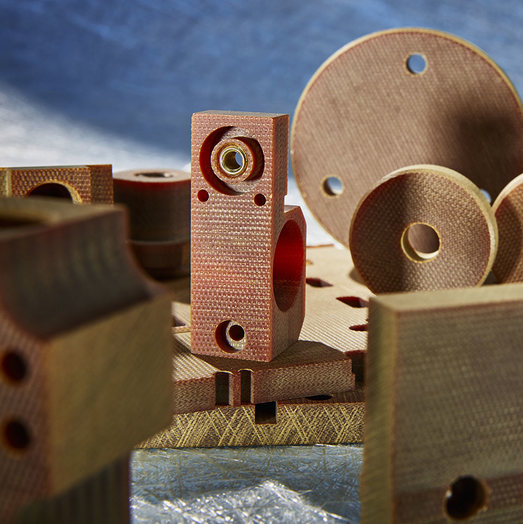

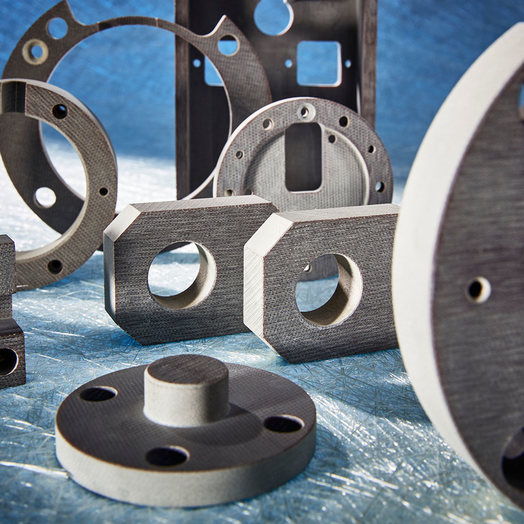

Thermal insulation is a critical component for many different press operations from laminate and veneer operations to automotive molded parts manufacturing. Insulation material boards are typically located between the work piece and the heated platen (heating plate). This special, compression resistant insulation prevents the hydraulic assemblies including cylinders and seals from being exposed to the heat of the platen.

Over time and thousands of cycles, the pressure and exposure to extreme heat, petroleum products and chemicals causes thermal insulation to breakdown and the material will begin to compress and delaminate. When this occurs, the press operation is no longer in calibration as a tolerance forms due to the compression of the insulation board. Most machine operators and maintenance staff are not aware that these insulation components need to be replaced after a certain time. This is because the boards are out of sight and hidden between the platen and the hydraulic pressing section.

European Machinery Services and top global producer of insulation components, Brandenburger, are here to help. Our service team can help you identify whether your machine is ready for new insulation material and help you determine the optimal replacement material. Many times, we discover the material suppled as OEM from the manufacturer can be replaced with a better performing product from Brandenburger. We also offer ceramic coatings to prevent petroleum and chemical contamination meaning the thermal insulation performs better and longer.

Brandenburger manufacturers a myriad of products related to thermal insulation in addition to insulation plates. BRA-FLEX* is an easy-to-install, chemical resistant pipe insulation material that yields significant gains in efficiency in thermal oil circulation systems. This material can reduce thermal transfer up to 200 degrees Celsius. This means access to machine service is far less dangerous for maintenance personnel and can dramatically reduce the escape of heat from the circulation pipes.

To keep your press equipment running safely and efficient with a goal of cost savings, consider the age of your machine and if it could be ready for new insulation material. We are always on standby to help.

Learn about Brandenburger insulator boards:

Contact Us For More Details

All product names, logos, and brands are property of their respective owners. All company, product and service names used in this website are for identification purposes only.