The Fastest Does Not Equal the Best

The arms race for to create the fastest edgebander has left many owners and operators frustrated – and that is putting it lightly. The sacrifice for speed is ultimately reliability. Servos must be used instead of pneumatic cylinders. It is proving out that servos aren’t as reliable, and machines designed for speed break down more often and are generally more expensive to own and operate.

The Altendorf edgebander models fall between a manual machine and today’s highly automated, speed machine. This means that the user keeps up with most production demands while still maintaining top-quality edging in an affordable, reliable package.

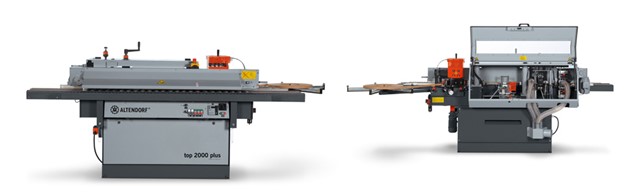

Top 2000 Plus

An edgebander that offers the essentials but tremendous versatility, the Top 2000 Plus is perfect for smaller workshops. Built with robust construction, the Top 2000 Plus is small enough to me mounted on casters making it easy to move as your shop grows.

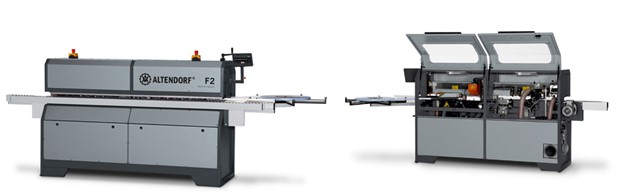

F 2

The perfect entry level edgebander, the Altendorf F 2 offers a 3.3M length, 10” touch screen, diamond-tipped premilling aggregate, top and bottom trimming and surface scraper.

F 4

The Altendorf F 4 is an edgebander with complete processing ability featuring a 4M machine length, 10” touch screen, diamond-tipped premilling aggregate, trim saw, top and bottom trimming, corner rounding and a surface scraper with dual tracing.

F 5

The Altendorf F 5 is a high performance edgebander offering a standard profile shaper, 10” touch screen, 4.3M machine length, diamond tipped premilling aggregate, trim saw, top and bottom trimming, corner rounding, surface scraper with dual tracing and buffer unit.

K 33

The Altendorf K 33 edgebander is the joinery champion of the wood industry. Standard options include 10” PLC touchscreen, 4.3M machine length, premilling aggregate, trim saw, top and bottom trimming, corner rounding, surface scraper, pneumatic roll cutting station, automatic central lubrication, gluepot interchangeable mount for PUR applications, support plate for edge material and double overhead pressure system. Airtronic Seamless Joint System featuring hot air banding technology is available as an option.

K 36

A slightly larger unit than the K 33, the K 36 has a powerful 14 kw transport system with a feed rate of up to 10M per second. Standard options include 10” PLC touch screen, 5.2M machine length, pre-milling aggregate, trim saw, top and bottom trimming, corner rounding, radius profile scraping, surface scraping with dual-tracing and a grooving saw unit. Airtronic Seamless Joint System featuring hot air banding technology is available as an option.

K 37

The K 37 boasts the maximum power from the K line of edgebanders. Standard specifications include 10” touch screen, 6M machine length, pre-milling aggregate, trim saw, top and bottom trimming, corner rounding, radius profile scraping, surface scraping with dual-tracing, buffer unit and a grooving saw unit. Airtronic Seamless Joint System featuring hot air banding technology is available as an option.