Solutions For The Furniture Industry

High performance in dividing requires high performance in destacking. Depending on the desired degree of automation, the material to be destacked and the complexity of the division, Anthon offers various solutions. These range from manual to semi-automatic to fully automatic destacking featuring a myriad of robotic integration possibilities.

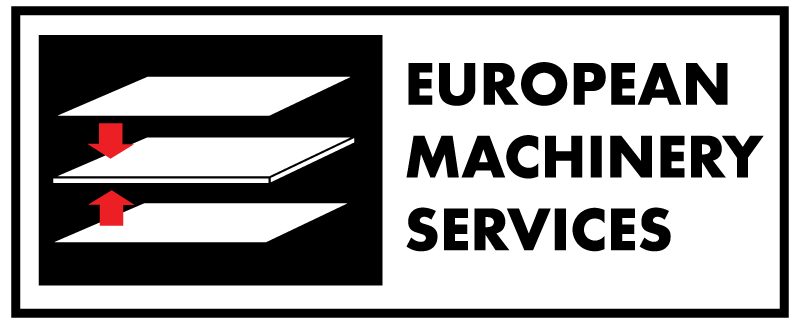

Compact angular plant for the furniture industry

—————–

- Very compact angular plant for panel format 2550 x 1350 mm

- Feeding of the panels by means of vacuum

- Package forming station for appropriate alignment of the panels before splitting

- Angular plant consisting of longitudinal saw with turntable and crosscut saw. Cutting height 180 mm

- Stacking as a combination of manual hand stacking and side gripper stacking for large formats

- Fully automatic protection and pallet feed

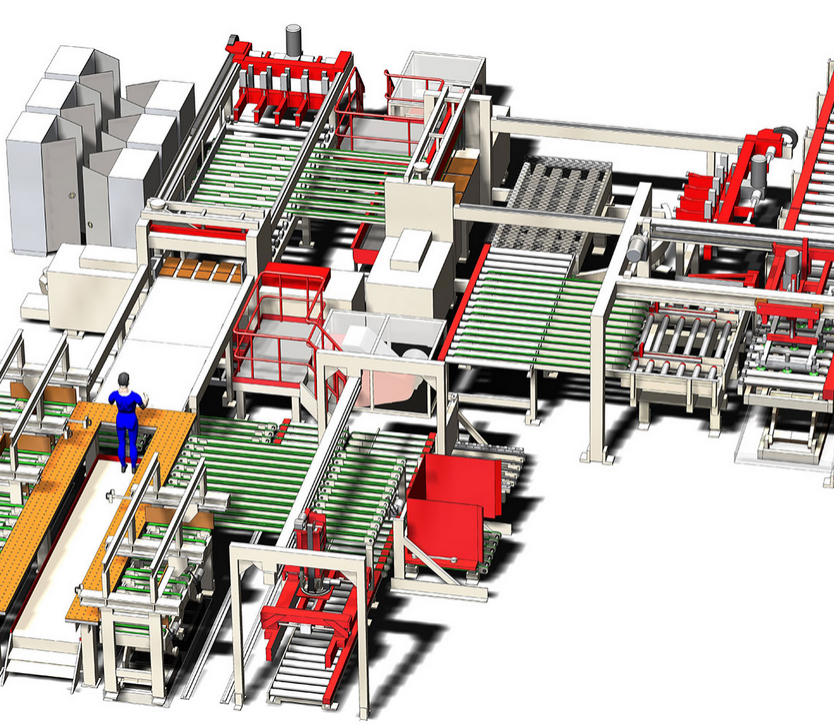

High-performance angular plant for the furniture industry

—————–

- Very powerful angular plant for panel format 5700 x 2700 mm

- With appropriate cutting patterns, sawing and stacking capacities of up to 150m³/h are possible

- Feeding the sensitive panels by means of vacuum

- Thin boards are transported with a separate high-performance feeder (nip roller)

- Package forming station for appropriate alignment of panels prior to dividing

- Angular plant consisting of longitudinal saw with turntable and 2 x crosscut saw. Cutting height 260 mm

- Paternoster between rip and cross-cut saws for the corresponding strip collection for optimum cross-cut saw utilisation

- 2 x fully automatic robot destacking including automatic protective panel handling

- Air-conditioned control cabinet container and central operator room

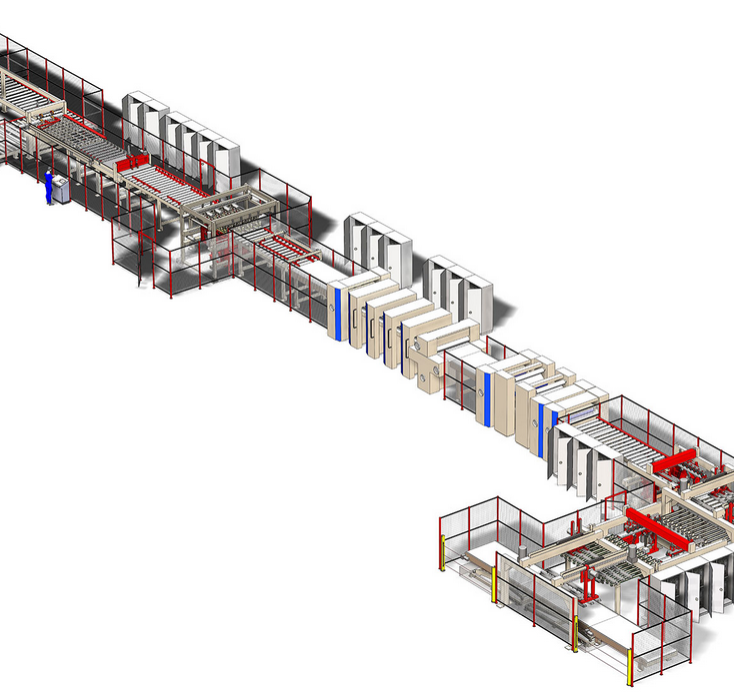

Multi blade saw for the furniture industry

—————–

- Multirip saw consisting of longitudinal and crosscut saw for dividing after laminating line

- Feeding and stacking before and after laminating line

- Continuous, uninterrupted feeding of the laminating line

- No interruption during stack change

- Longitudinal and cross-cutting saws equipped with hoggers on zero sides

- High-performance stacking with up to 23 cycles/minute

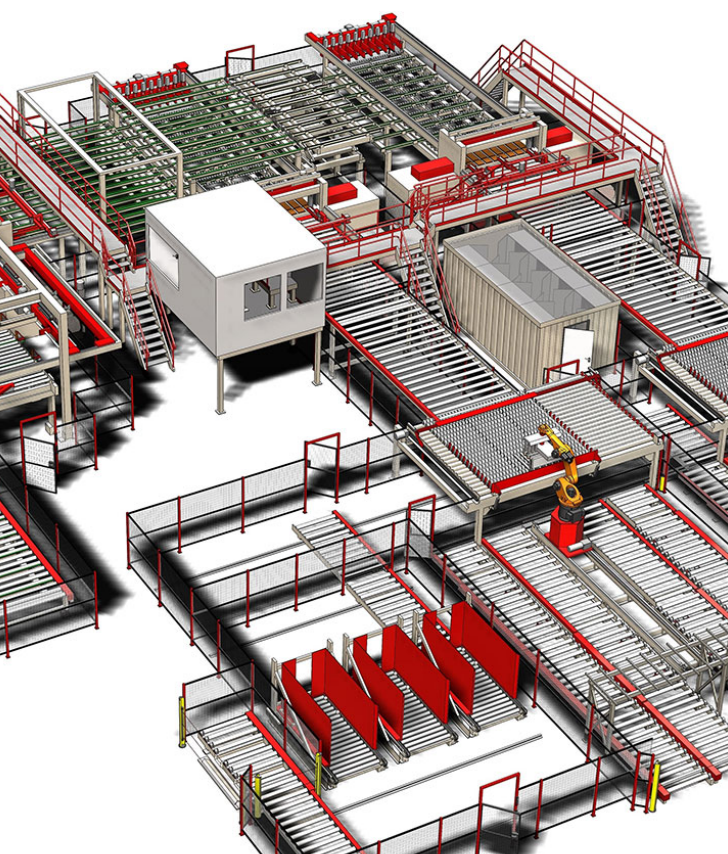

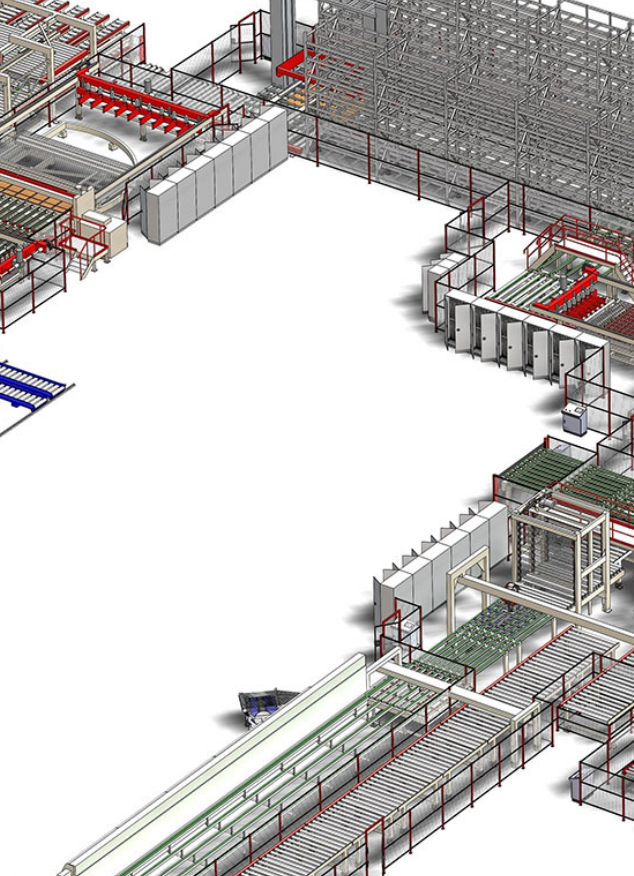

Angular plant with connected batch size 1 plant for the furniture industry

—————–

- Turnkey project consisting of angular plant and batch size 1 plant

- Angular plant for the division of series parts

- Panel size 5850 x 2550 mm

- Feeding the panels by means of vacuum

- Package forming station for appropriate alignment of the panels before dividing

- Angular plant consisting of longitudinal saw with turntable and crosscut saw. Cutting height 180 mm

- Destacking as a combination of fully automatic robot destacking and rack destacking for half-size formats for connected batch size 1 production

- Fully automatic protection and pallet feed

- Batch size 1 plant with raw panel storage, automatic angular plant for single panels, edging and drilling machines, sorting store

- Feeding the saw from a high-bay storage system

- Winkelanlage für die Aufteilung von Sonderteilen. Immer Einzelplatte

- Plattenformat 2850 x 1800 mm

- Leistung bis zu 6 Teile/Minute

- Kantenanleimmaschine

- Sortierspeicher mit nachfolgender Bohrmaschine

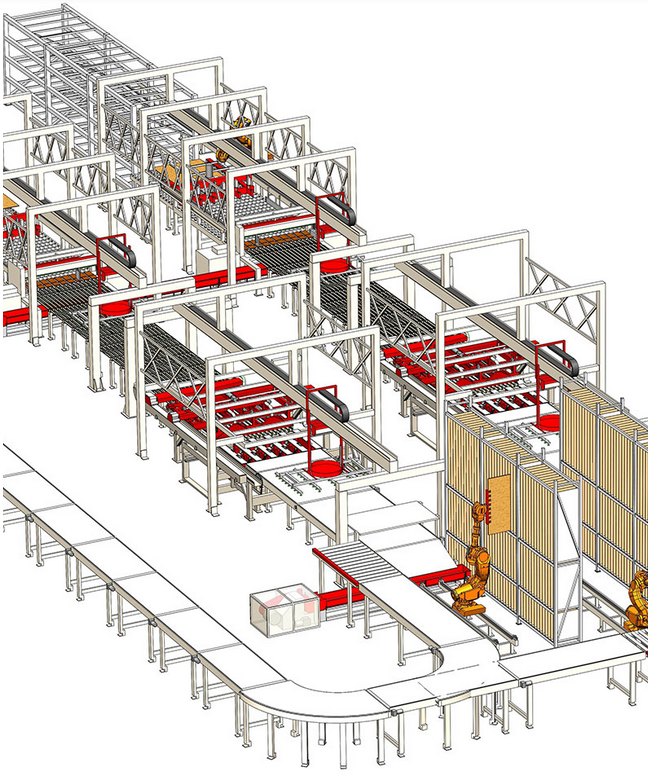

Batch size 1 High performance unit

—————–

- Storage rack

- Mobile feeding robot

- Anthon pressure beam saw with panel puller. Forward and reverse speed 150m/min. Cutting height single panel. Max. 60 mm

- Conveyor technology (belt conveyors with measuring stations)

- Rotating vacuum feeder for returns after longitudinal saw

- Crosscut saw with slide-in infeed. Multirip saw with 2 hoggers and 7 sawing units

- Conveyor technology after panel division

- Rotatable vacuum feeder for returns after multi-blade saw

- Pick-up robot with intermediate and remaining parts store

- Panel dimensions infeed 2850 x 2200 mm

- Output per plant: 20 parts/minute