Ness Thermal Oil Systems, Oil Filtration Systems & Light Ends Removal

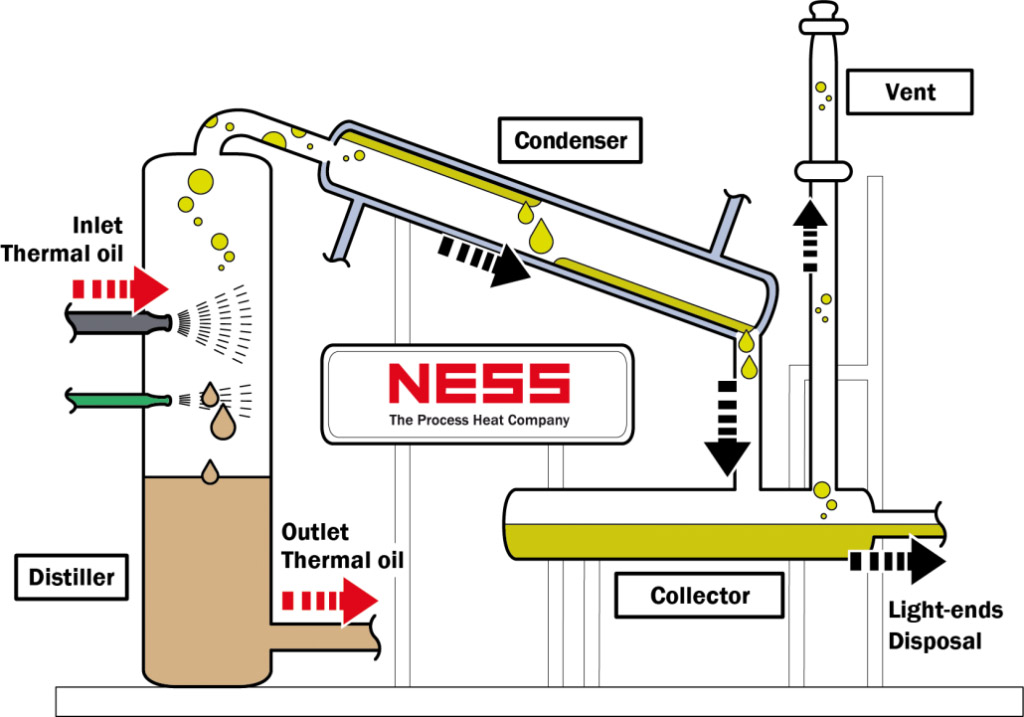

Operating machinery and equipment that requires high temperature thermal oil circulation without a particle filtration system can cause poor performance, premature wear and product quality issues. When oil reaches high temperatures, “light ends” are formed as a byproduct of the heating process. Light ends are considered volatile hydrocarbon products. Examples include propane, butane and naptha. These light ends reduce the flash point of the oil system thus preventing optimal operating temperature from being achieved. Light ends also cause cavitation of the circulating pumps leading to premature failure and substandard operating performance. What this means in laymen’s terms is that your hot oil system will only operate properly if light ends are continuously filtered and removed from the oil system.

European Machinery Services is proud to partner with Ness Wärmetechnik GmbH to offer their premium light ends removal systems for US operations. Our combined experience with thermal oil system installation, thermal systems management and value-add processes exceed many decades of expertise. Please contact EMS if you would like more information and consultation regarding your thermal oil system and how to maintain proper, long-term performance.

Preventive measures are always much cheaper than a breakdown!

All product names, logos, and brands are property of their respective owners. All company, product and service names used in this website are for identification purposes only.